In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

The thermal energy input per 1 ton of clinker production is estimated. This is because from the point of view of energy consumption clinker production is the core of the cement production process. Following the thermal energy required for clinker production, 'the raw material process', 'the

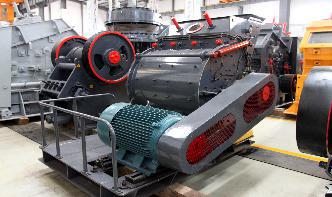

Cement Clinker Processing Plant. In fact cement clinker processing plant is divided into four phases including limestone mining the raw material crushing raw material grinding cement clinker burning cement clinker grinding 1 limestone mining the limestone ore crushing process and through a variety of methods to transport lime stone base. Live Chat

Portland Limestone Cement (PLC) Manufacture CaCO Cli ti CCOCO+CO 3 (limestone) 2SiO 2•Al 2O 3 (clay, shale) Fe 2O 3 (iron oxide) SiO 2 (silica sand) CO 2 Calcination: CaCO 3 → CaO + CO 2 ~ ton CO 2 per ton of clinker SO (s ca sa d)

About 1'600 kg of raw material and 200 kg of coal are needed to produce 1 ton of clinker. On the other hand we have the waste problem. Waste is produced daily and everywhere in the world.

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

The average needs for 1 ton of clinker = Worldwide cement production in 2007 was billion tonnes, and will rise to billion tonnes in 2015. 1'300 kf of limestone. Bauxite, iron oxide, silica, ..

Determination of Bond Work Index of Lucky Cement Limestone Pakistan Niaz Muhammad Shahani, Zhijun Wan, Abdullah Rasheed Qureshi, Muhammad Ali, Naseem Ali Abstract—The Bond work index is a research methodology, which is widely used for the estimation of power required to grind the materials.

Assuming a clinker cost at 25/ton, the plant would likely save million per year. From this cost savings estimate, the cost of the additives will have to be subtracted. Additive costs vary depending on the source and transportation cost of the additives; the limestone dust and cement kiln dust are often waste byproducts with a zero or negative cost (a disposal cost).

Portland Limestone Cement (PLC) Manufacture CaCO Cli ti CCOCO+CO 3 (limestone) 2SiO 2•Al 2O 3 (clay, shale) Fe 2O 3 (iron oxide) SiO 2 (silica sand) CO 2 Calcination: CaCO 3 → CaO + CO 2 ~ ton CO 2 per ton of clinker SO (s ca sa d) Fuel: ~ to ton CO 2 per ton of clinker Kiln Heat per ton of clinker 3CaO•SiO 2 CCO CSO2H O 2CaO•SiO 2 3CaO•Al 2O 3 4CaO•Al 2O

The overall level of CO 2 output, about 1 ton/ton clinker, is almost equally contributed by the calcination of limestone and the combustion of fuels and makes the cement industry one of the top two manufacturing industry sources of this greenhouse gas. The enormous demand for cement and the large energy and raw material requirements of its manufacture allow the cement industry to consume a wide variety of .

In cement plant, producing each 1 ton of Portland cement needs at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials, gypsum). Grinding operation consumes power about 60% of total power in cement plants, raw material grinding takes more than 30%, while coal mill used in cement palnt consumes 3%, cement grinding is about 40%.

It takes between pounds of raw material to make one ton of cement, the bulk of the raw material being limestone. Let's say the ratio is tons limestone for every ton of cement ...

It takes between pounds of raw material to make one ton of cement, the bulk of the raw material being limestone. Let's say the ratio is tons limestone for every ton of cement ...

As with the crushing, rawmilling, and clinkering steps at the quarry plant, step 6, the finishmilling step, is also energyintensive: grinding the ~5/8" clinker nodules, which are harder than limestone, back into powder usually consumes ~3565 kWh/ton.

At least 3 tons of materials need grinding for producing 1 ton of silicate cement (including all kinds of raw materials, such as fuel, clinker, mixture and plaster). According to the statistics, the dry process cement production line consumes more than 60% of the power of the whole plant, with raw material grinding taking up 30%, coal grinding about 3%, cement grinding about 40%.

Expense in mining 1 ton limestone in India, crusher plant for Stone Crusher Machine Price in India cost >>Price; limestone quarrying and cement production. unit cost per ton of quarrying limestone in cement industry the south african cement industry jan derived from the calcining of clay, sand and limestone a natural resource with clinker in.

limestone cement production . offers 2,596 limestone cement production products. About 62% of these are cement making machinery, 14% are brick making machinery, and 4% are mine mill. A wide variety of limestone cement production options are available to you, such as free samples.

إذا كنت مهتما في شركتنا أو المنتجات، ترحيب لزيارة شركتنا أو المكاتب المحلية. يمكنك أيضا الحصول على الاتصال معنا من خلال الاستشارات عبر الإنترنت، وتقديم الطلب الجدول، والبريد الإلكتروني والهواتف. موظفينا يجب بكل إخلاص تقديم معلومات المنتج، تطبيق المعرفة و خدمة جيدة بالنسبة لك.

Copyright © .CNمحطم All rights reserved.Sitemap